Shaping up the benefits of offsite manufacture of brick slip soffit systems and intricate brick features

Contents |

[edit] Introduction

Whilst traditional building methods still have their place, the advantages of offsite construction in addressing both the skills shortage and solving the industry’s drive for quality will motivate many across the sector to adopt these efficient practices. In light of this, how can the offsite manufacture of products such as brick slip soffit systems enable specifiers to respond to these industry challenges whilst at the same time achieve the most complex architectural designs?

[edit] Incredible brickwork

With offsite methods, architects can create intricate brickwork designs that are guaranteed to translate onsite and ensure the same quality finish every time. Consistency and quality were essential at the Defence and National Rehabilitation Centre (DNRC) in Loughborough. Over 1000 brick slip feature arches and just under 3km of offsite cornice were manufactured and designed by IG Masonry Support. It would have been a time-consuming, highly-skilled task to create arches and cornice using traditional methods onsite, therefore IG utilised its offsite solutions to create identical arches of various designs and cornice detail that would achieve the architect’s desired aesthetic.

The uniformity that was essential to this project can run the risk of being compromised if traditional trades are employed. However, with modular construction this replication simply isn’t an issue. Taking the construction of complex brick features offsite into factory-controlled conditions drives the level of quality and consistency that is needed to achieve architectural excellence, and often reaches further than the capabilities of traditional build processes, particularly on large-scale developments.

[edit] Addressing the skills gap

Rethinking the way we design, engineer and construct buildings will help deliver projects quicker, better and with a greater degree of precision. Building better with these modern methods of construction plays a part in plugging the skills gap by reducing onsite labour whilst addressing the high demand for new buildings.

Furthermore, offsite manufacturing is a potential solution to mitigating risk. With prefabricated products everything is fixed in a factory-controlled environment where quality is guaranteed every time. When it comes to installation, architects can rest assured that their design will be installed quickly with reduced risk.

[edit] Bespoke solutions

At IG Masonry Support, not only do we understand that architects need to be given creative authority over prefabricated brick features. We also realise the importance of regulatory compliance and quality.

Achieving deep brick soffits and intricate brick bonds around window heads and openings is quick, easy and cost-efficient to achieve with our Brick On Soffit Systems (B.O.S.S. and B.O.S.S.+). These tailor-made bespoke solutions are designed and manufactured to meet the client’s specification and are highly adjustable, enabling architects to design various shapes and depths of brick soffits whilst accommodating a wide range of bond patterns.

|

|

IG’s latest innovation, B.O.S.S.+, is a mechanically-fixed brick slip soffit system. As well as being an easy-to-install, quality system, B.O.S.S.+ was developed to meet with the fire safety regulations highlighted in Approved Document B, building regulations for non-combustible materials for use in the external walls of residential dwellings over 18 metres in height. For added security, all the brick slips on this BBA-approved product are attached to the stainless-steel framework with a robust mechanical fix.

IG Masonry Support has combined experience with innovation to design and manufacture the most practical and advanced range of ‘patented’ stainless steel masonry support solutions, brick slip soffit systems and intricate brick features for the construction industry. We provide comprehensive technical support for all our products and offer a free design service for our range of off the shelf and bespoke solutions.

Offering endless creative scope for architects, our easy-to-install solutions can deliver significant reductions in installation time by up to 90%. Any higher initial costs can be offset by saving time and money in terms of labour. A quality finish that meets the required aesthetics and blends seamlessly with the surrounding brickwork can also be achieved.

For more information visit the IG Masonry Support website.

--IG Masonry Support 17:21, 21 Sep 2020 (BST)

[edit] Related articles on Designing Buildings Wiki

Featured articles and news

Twas the site before Christmas...

A rhyme for the industry and a thankyou to our supporters.

Plumbing and heating systems in schools

New apprentice pay rates coming into effect in the new year

Addressing the impact of recent national minimum wage changes.

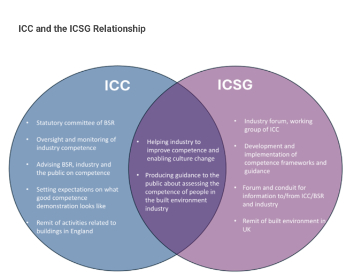

EBSSA support for the new industry competence structure

The Engineering and Building Services Skills Authority, in working group 2.

Notes from BSRIA Sustainable Futures briefing

From carbon down to the all important customer: Redefining Retrofit for Net Zero Living.

Principal Designer: A New Opportunity for Architects

ACA launches a Principal Designer Register for architects.

A new government plan for housing and nature recovery

Exploring a new housing and infrastructure nature recovery framework.

Leveraging technology to enhance prospects for students

A case study on the significance of the Autodesk Revit certification.

Fundamental Review of Building Regulations Guidance

Announced during commons debate on the Grenfell Inquiry Phase 2 report.

CIAT responds to the updated National Planning Policy Framework

With key changes in the revised NPPF outlined.

Councils and communities highlighted for delivery of common-sense housing in planning overhaul

As government follows up with mandatory housing targets.

CIOB photographic competition final images revealed

Art of Building produces stunning images for another year.

HSE prosecutes company for putting workers at risk

Roofing company fined and its director sentenced.

Strategic restructure to transform industry competence

EBSSA becomes part of a new industry competence structure.

Major overhaul of planning committees proposed by government

Planning decisions set to be fast-tracked to tackle the housing crisis.

Industry Competence Steering Group restructure

ICSG transitions to the Industry Competence Committee (ICC) under the Building Safety Regulator (BSR).

Principal Contractor Competency Certification Scheme

CIOB PCCCS competence framework for Principal Contractors.

The CIAT Principal Designer register

Issues explained via a series of FAQs.